Tel :+ 86 13927313502

E-mail : 18902622229@163.com

Breathe Easy: Exploring Advanced Solutions in Compressed Air Treatment

Efficient and Effective Solutions for Compressed Air Treatment

The Importance of Compressed Air Treatment

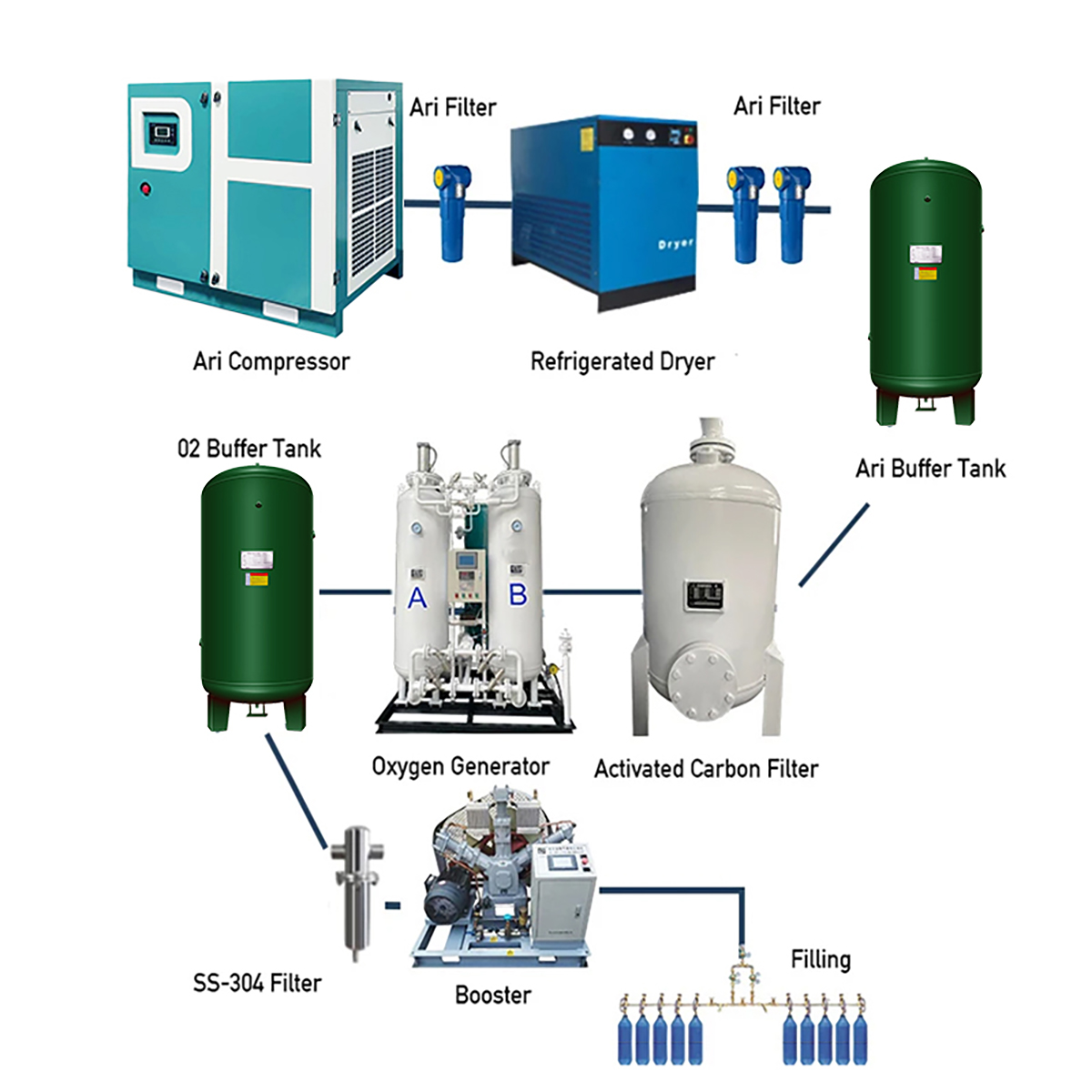

Compressed air is a widely used utility in various industries, ranging from manufacturing to healthcare. However, it is crucial to ensure that the compressed air used in these applications is free from contaminants and moisture. This is where compressed air treatment comes into play. It involves the process of filtering, drying, and purifying compressed air to meet specific quality standards.

Common Issues in Compressed Air

Compressed air often contains impurities such as dust, oil, water vapor, and microorganisms, which can adversely affect the performance and lifespan of pneumatic systems and end-use applications. These impurities can lead to component failures, decreased product quality, and increased maintenance costs. Therefore, it is essential to implement advanced solutions for compressed air treatment.

Exploring Advanced Solutions

1. Filtration: Filtration is the first line of defense in compressed air treatment. Advanced filtration systems incorporate high-efficiency filters to remove solid particles, dust, and oil mist. These filters utilize multiple stages, including pre-filters and coalescing filters, to achieve optimal air purity.

2. Desiccant Dryers: Desiccant dryers are effective in removing moisture from compressed air. They utilize desiccant materials such as activated alumina or silica gel to absorb water vapor. These dryers are capable of achieving extremely low levels of dew point to prevent corrosion, freeze-ups, and contamination in sensitive applications.

3. Adsorption Filters: Adsorption filters are designed to remove oil vapor, odors, and other gaseous impurities from compressed air. These filters employ activated carbon or other adsorbent materials to trap and eliminate these contaminants, ensuring clean and odor-free compressed air.

4. Heatless Regenerative Dryers: Heatless regenerative dryers offer energy-efficient drying solutions. They use a twin-tower design that allows continuous drying cycles. During the regeneration phase, a portion of the dry compressed air is redirected to desorb the moisture from the desiccant material, ensuring uninterrupted dry air supply.

5. Condensate Management: The condensate generated during the compression and cooling process needs to be effectively managed to prevent environmental harm and comply with regulations. Advanced condensate management systems combine oil-water separators, activated carbon filters, and automatic drains to separate oil and ensure proper disposal.

Benefits of Advanced Solutions

Implementing advanced solutions in compressed air treatment offers numerous benefits:

- Enhanced product quality and reliability

- Extended equipment lifespan and reduced maintenance costs

- Improved energy efficiency and reduced operating costs

- Compliance with industry standards and regulations

- Minimized environmental impact

- Enhanced safety for personnel and equipment

Conclusion

Compressed air treatment is an essential aspect of ensuring the optimal performance of pneumatic systems and end-use applications. Advanced solutions, such as filtration, desiccant drying, adsorption filtration, heatless regenerative drying, and condensate management, play a vital role in achieving clean, dry, and contaminant-free compressed air. By implementing these advanced solutions, industries can enjoy improved efficiency, reliability, and cost savings in their compressed air systems.

Huizhou Dehong Air Compressor Co., Ltd. is a high-tech enterprise that specializes in the research and development, production and sales of pneumatic equipment. Its main products include screw air compressors, dryers, gas storage tanks, pipeline filters, nitrogen generators, pneumatic equipment, pneumatic tools and pneumatic components.